Detailed diagrams of in-stock spare part model numbers

ASME NB Certified: Air, Steam & Water

European CE Approved

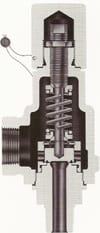

Sizes 1″ X 2″ to 20″ X 24″. Actual orifice areas from 0.150 to 176.7 square inches. Pressures from 15 to 6000 psig. Temperature range from -450° to +1500°F. Steel body and bonnet with stainless steel trim.

Optional balanced bellows design isolates working parts and top-works from fouling or corrosive service, and nullifies the effects of back pressure on valve performance.

The “D” to “T” orifices meet API Standard 526 covering orifice areas and center-to-face dimensions. Super capacity types range from “W” (63.62 sq. in.) to “Z” (176.7 sq. in.) and have a maximum set pressure limit of 300 psig.

Optional materials of construction include complete 316 stainless steel, *Monel®, and *Hastelloy C®. Also available with materials in compliance with NACE standards. Higher temperature models use chrome moly body and bonnet.

Optional O-ring elastomer seat available for maximum tightness.

Applications: air, steam, gas, vapor, and liquid process applications.

ASME NB Certified: Air, Steam & Water

European CE Approved

Sizes 1″ X 2 to 12″ X 16″. Actual orifice areas from 0.15 to 109 square inches. Pressures from 20 to 6170 psig. Temperature range of -450° to +500° F. Steel body and bonnet with stainless trim. Semi-nozzle design.

The “D” to “T” orifices meet API Standard 526 covering orifice areas and center-to-face dimensions. Full bore designs available with 1″ through 12″ inlets and orifice areas from 0.719 to 109 square inches giving maximum capacity for a given inlet size. All stainless snap acting and modulating non-flowing pilot controls minimize product loss and provide maximum resistance to corrosion.

Standard O-ring elastomer seat main valve and pilot control minimizes fugitive emissions and allows operation within 95% of set pressure. Materials include *Viton®, Buna N, ethylene propylene, silicone and *Teflon®. Optional materials of construction include complete 316 stainless steel.

Applications: air, steam, gas, vapor, and liquid services where maximum seat tightness, operating pressures and precise adjustment are required. Excellent for natural gas pipeline and compressor service.

ASME NB Certified: Air & Steam

Sizes 3/4″ X 1″ to 1-1/2″ X 2″ (2850) and 3/4″ X 1-1/4″ to 2″ X 3″ (2856). Effective orifice areas from 0.098 to 1.048 square inches. Pressures from 15 to 300 psig. Temperature range of -20° F to +750° F (2850) and -450° F to +400° F (2856).

Materials of construction include stainless steel body and trim (2850) and bronze/brass body and trim with bronze bonnet (2856).

Applications: air, steam, gas, vapor and non-Code liquid applications where service is compatible with stainless steel (2850) or brass and bronze (2856). Also suitable for cryogenic applications.

ASME NB Certified: Air, Steam & Water

Sizes 1/2″ X 1″ & 3/4″ X 1″ (1890) and 1/2″ X 3/4″ & 3/4″ X 3/4″ (1896M). Effective orifice areas of 0.077 (liquid) and 0.089 (vapor) square inches. Pressures from 15 to 800 psig for stainless steel (1890) and 15 to 300 psig for bronze (1896M). Temperature range from -20° F to +750° F (1890) and -450° F to +400° F (1896M).

Materials of construction include stainless steel body and trim (1890) with bronze bonnet (1896M).

Applications: air, steam, gas, vapor and liquid process applications (1890) and where service is compatible with brass and bronze (1896M). Also suitable for cryogenic applications.

ASME NB Certified: Air, Steam & Water

European CE Approved

Sizes 1/2″ X 1″ to 1-1/2″ X 2-1/2″. Effective orifice areas from 0.068 to 0.573 square inches. Pressures from 15 to 6500 psig. Temperature range of -450° F to +750° F.

Stainless steel body and trim with carbon steel bonnet. Optional materials of construction include complete 316 stainless steel, *Monel®, and *Hastelloy C®. Materials suitable for NACE service available.

Available with threaded, flanged, socket weld, welding nipple or sanitary connections. Optional O-ring seat for ultimate tightness. Maximum blow down of 10% to 20% on all fluids. Balanced design available in “C” and “D” orifices which nullify effects of back pressure.

Applications: air, gas, vapor, and liquid process service.

ASME NB Certified: Steam

Sizes 1-1/4″ X 1-1/2″ to 6″ X 8″. Actual orifice areas from 0.136 to 11.39 square inches. Pressures from 15 psig to 1000 psig. Temperature limit to 1000° F. Steel body and open bonnet with stainless steel trim. Chrome moly body above 800° F.

Double adjusting ring design to meet the blow down and overpressure standards of Section I of the ASME Code. Temperature equalizing disc for maximum seat tightness. Full nozzle design for longer life and ease of maintenance. One piece guide mounted low in the body for positive alignment.

Applications: steam boilers

ASME NB Certified: Steam & Air

Sizes 1″ X 2″ to 4″ X 6″. Actual orifice areas from 0.150 to 7.087 square inches. Pressures from 15 to 1500 psig. Temperature range from -20° F to +1000 F. Steel body and bonnet with stainless steel trim.

Double blow down ring design meets the requirements of Section I of ASME Code. Temperature equalizing disc for maximum seat tightness. Available with exposed spring (6400) or closed bonnet (6600). Full nozzle design for ease of maintenance.

Applications: steam boilers (6400) and organic fluid vaporizers or hot water boilers (6600).